NOZZLE SPRING FORCE

Nozzle spring force affect on the idle condition.

..................................................................................................................................................................................

PROCEDURE:

STEP1

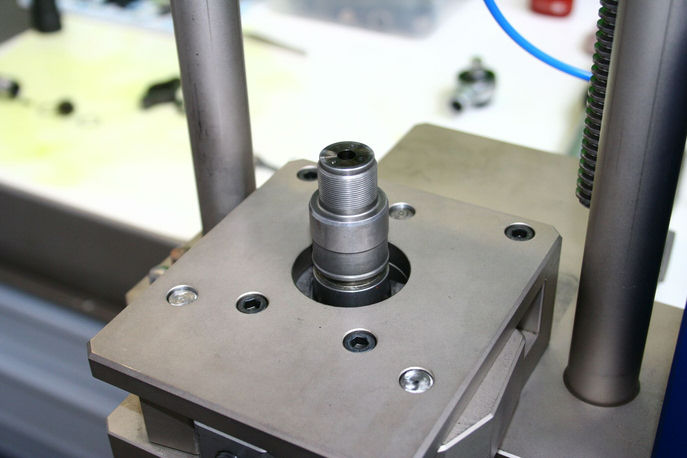

Fix the body injector in the dedicated centering plate as shown in the picture. Choose a part of the body to avoid the uncorrected centering (avoid bevels).

STEP2

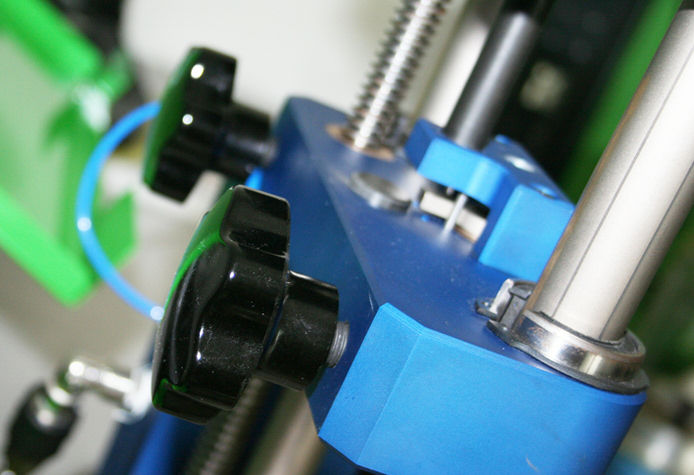

Assemble the gauge head DX75737 (dial gauge pull up pin, n°18 optional case) with the dial gauge.

Screw the head DX75626 (pin with probing small plate n°6 basic case) assembled with the head DX75627 (probing pin for coil measuring, n°8 basic case) on the slot probe pin exit.

Fit the dial gauge in the dedicated front slot and set it in cents.

STEP3

Insert into the body injector the shim, the spring and the pressure pin.

STEP4

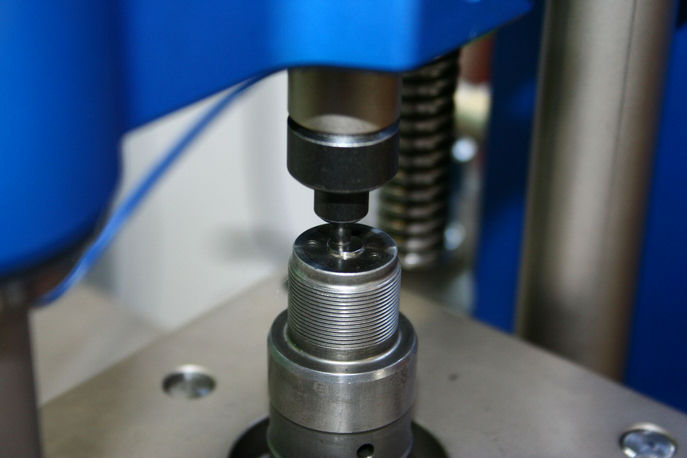

Place the fixed injector in order to make the head touch the surface where the nozzle fits. Zero the gauge and move the crossbeam down until the dial gauge will read 1 mm.

Block the vertical motion and reset the dial gauge.

STEP5

Place the injector so that the probing head lays on the pressure pin. Block the longitudinal motion.

STEP6

Set the air pressure to 0 bar.

Activate the pneumatic control and increase the air pressure until the dial gauge will read zero.

The pressure read will be considered as the nozzle spring force.

END