NEEDLE LIFT

PROCEDURE:

STEP 1

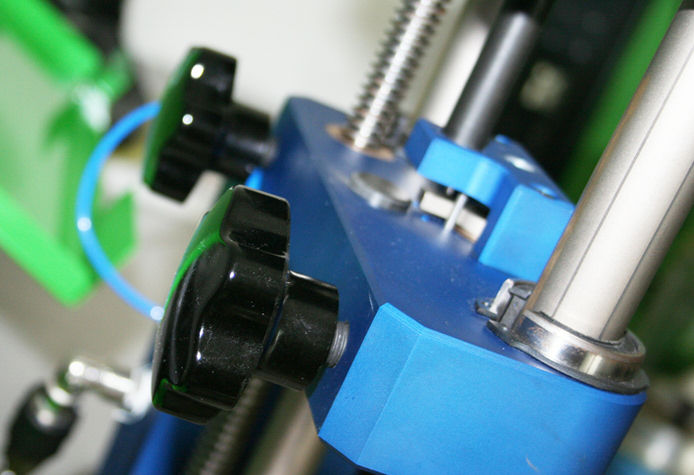

Assemble the gauge head DX756735 (n°9 case 2) with the dial gauge and fit it in the dedicated front slot.

Screw in the slot probe pin exit the head DX75626 (n°6 case 1) assambled with the head DX75634 (n°9 case 1).

Fix the instrument and set it in cents.

STEP 2

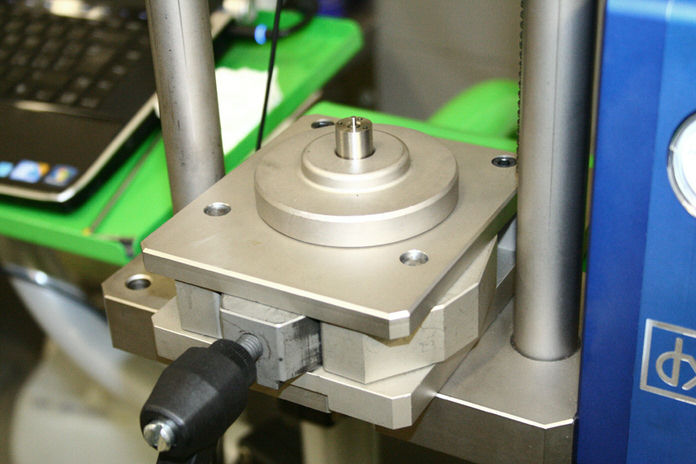

Using the dedicated tool DX75622 (n°1 case 1)

place the nozzle, within the needle, on the Tricky-Tech plate so that the nozzle it self results aligned with the dial gauge exit.

STEP 3

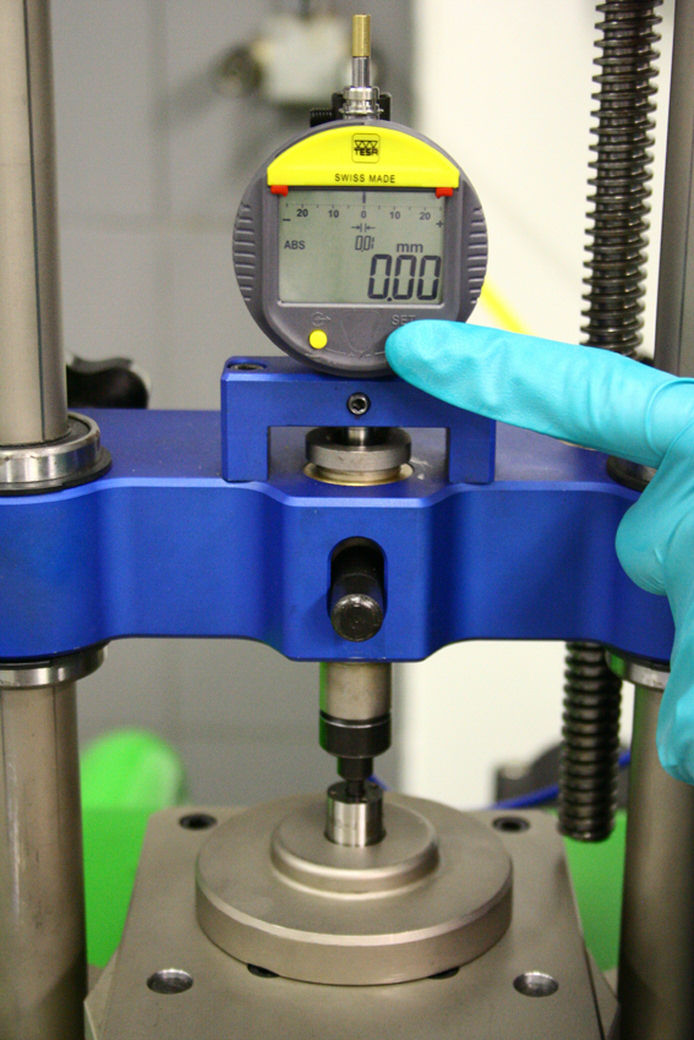

Controlling that the needle pin fits perfectly inside the head previously assembled, move down the moveable crossbeam until the surface of the head touches the base of the needle and the pneumatic piston movement lever moves a little bit higer from the rest position.

Lock the vertical movement and reset the dial gauge.

STEP 4

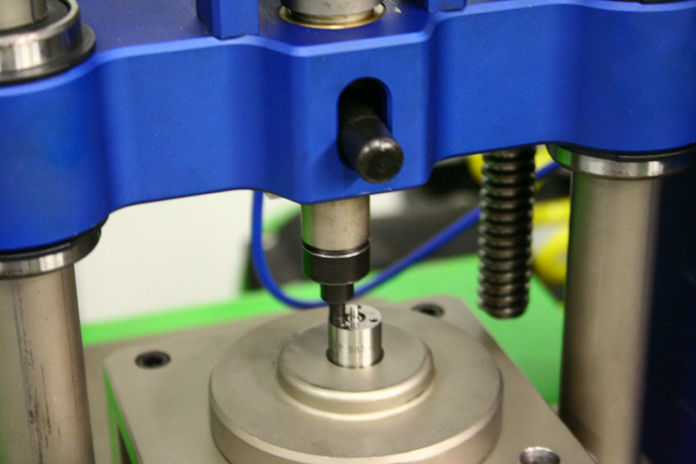

Lift up the pneumatic piston movement lever so that the needle pin comes completly of the head.

Move gently the tool where the nozzle is fitted on and release the dial gauge head so that it will be in contact with the nozzle surface.

The read measure is the needle lift.

END