ARMATURE LIFT

PROCEDURE:

STEP 1

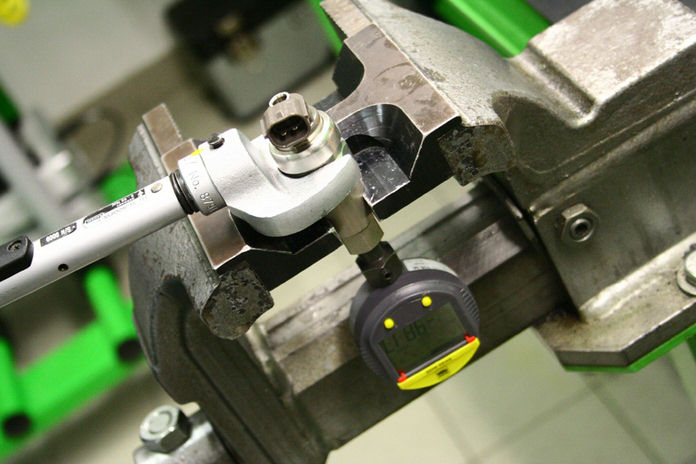

Assemble the head DX75631 (n° 12 case 1) with the dial gauge and fit it in the dedicated dial gauge holder for coil measuringe DX75636 (n°15 case 2). Set the imstrument in microns.

STEP 2

Reset the dial gauge placing the dial gauge holder (DX75636) in contact with a grinded surface.

STEP 3

Insert in the coil of the injector that has to be tested the armature lift shim and screw the dial gauge holder in the solenoid itself.

Tight the solenoid using the torque that has to be used to assemble the solenoid on the injector. Check the Tricky -Tech data sheet.

Note the measure. A MEASURE

STEP 4

Repeat the steps 2 and 3 but this time using, instead of the coil of the solenoid of the injector, the test solenoid (a G2 type top backleakage solenoid).

ATTENTION:ATTENZIONE: the shim to fit inside the solenoid is the same shim used before, that it means the shim of the injector that has to be tested.

Insert the shim inside the test solenoid.

Screw the dial gauge holder in the solenoid and tighten it with the correct tightening torque (same torque as in step 3).

Note the measure. B MEASURE

STEP 5

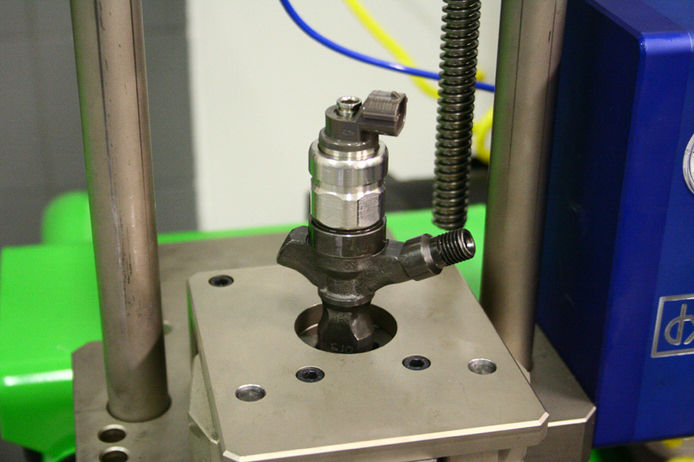

Using the test solenoid assemble completely the top part of the injector, being sure to tighten the solenoid using the tightening torque specified on the Tricky-Tech data sheet.

ATTENTION: the shim to fit inside the solenoid is the same shim used before, that it means the shim of the injector that has to be tested. Remember to insert inside the solenoid the solenoid spring without the solenoid spring shim.

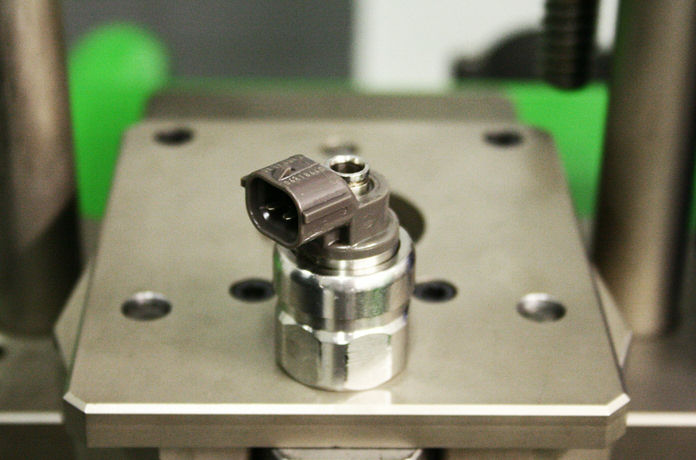

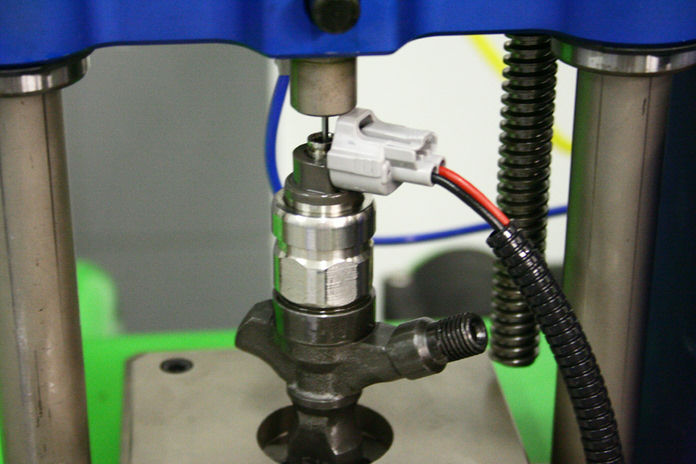

Fix the body injector in the dedicated centering plate as shown in the picture. Choose a part of the body to avoid the uncorrect centering (avoid bavels).

STEP 6

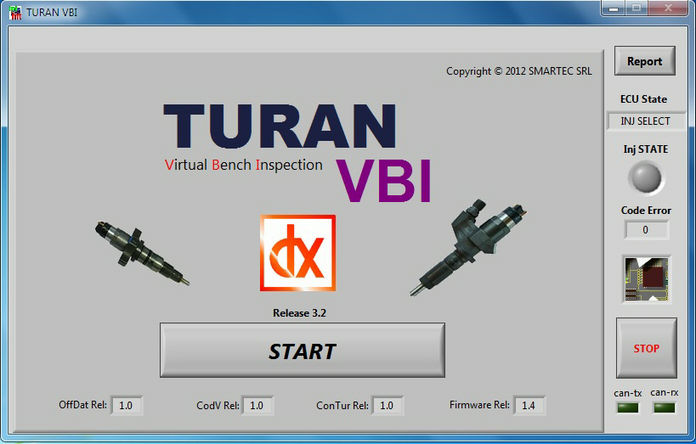

Be sure that the electrical connection of the Turan are well connected (Control unit, EPS, laptop).

STEP 7

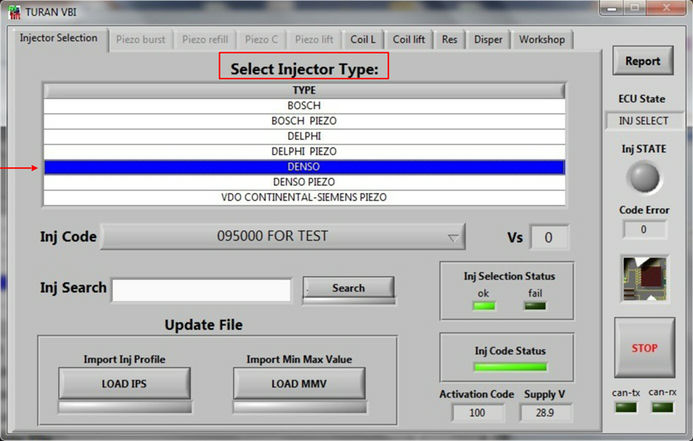

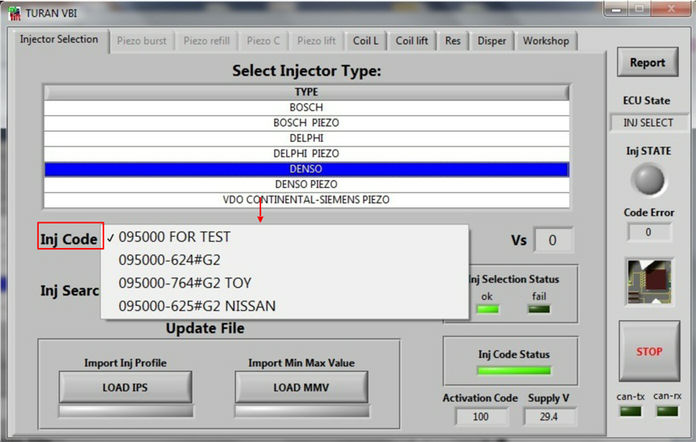

Open the Turan software and click on the "Start" button.

Select "Denso" on the "Type" menu and the code of the injector to test on the "Inj code" menu.

STEP 8

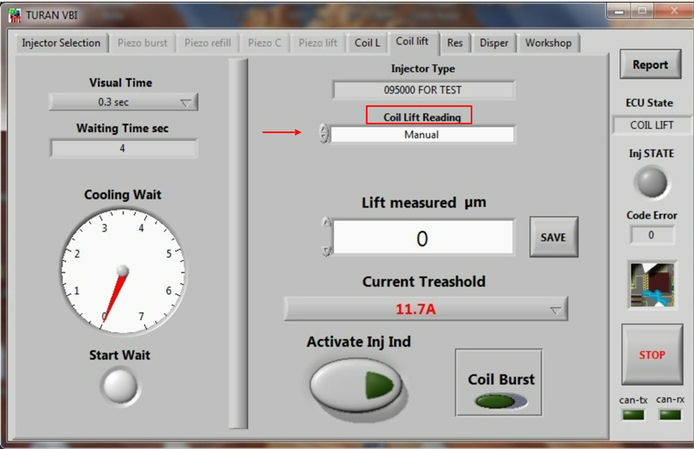

Click on "Coil lift" on the test menu selection and, using the dedicated terminal cable, connect the "coil" cable to the injector.

Move down the movable crossbeam so that the gauge head can pass into the solenoid hole. Stop when the gauge head touches the armature inside the solenoid. Be sure that the head does not get stuck on the solenoid spring.

STEP 9

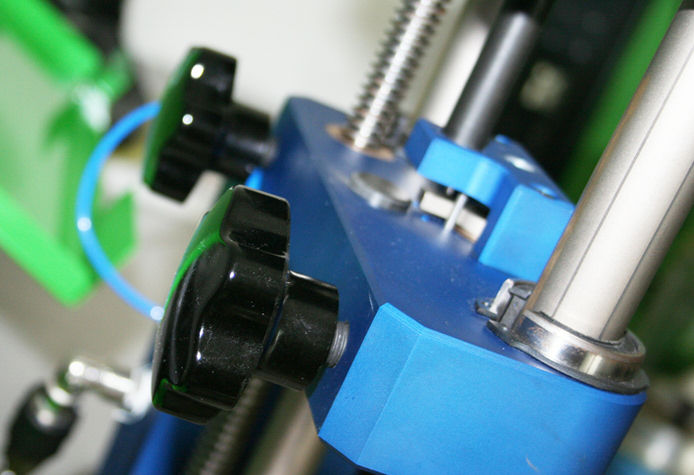

Lock the vertical and longitudinal motion.

STEP 10

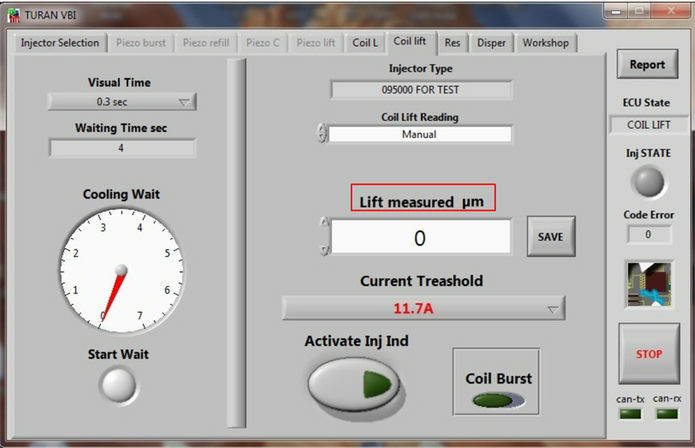

On the Turan software select “Auto” on the “Coil lift reading” menu and wait until the gauge starts to communicate with the software.

Activate the reading by clicking on the “Activate Inj Ind” button and wait until the software ends the test.

On the “Lift measured μm” window will appear the value of the coil lift electrically measured. Note the measure. (TURAN MEASURE)

ATTENTION: this lift is not the real armature lift of the tested injector.

STEP 11

Evaluate the real armature lift of the injector as follow:

ARMATURE LIFT = TURAN MEASURE - A MEASURE + B MEASURE

END